CellDEG GmbH

enhancing photoautotrophic growth

patented membrane bioreactors

novel HDC photobioreactor systems for extreme

biomass concentration and highest productivity

HighDensityCultivation-Technology

membrane mediated CO2 supply

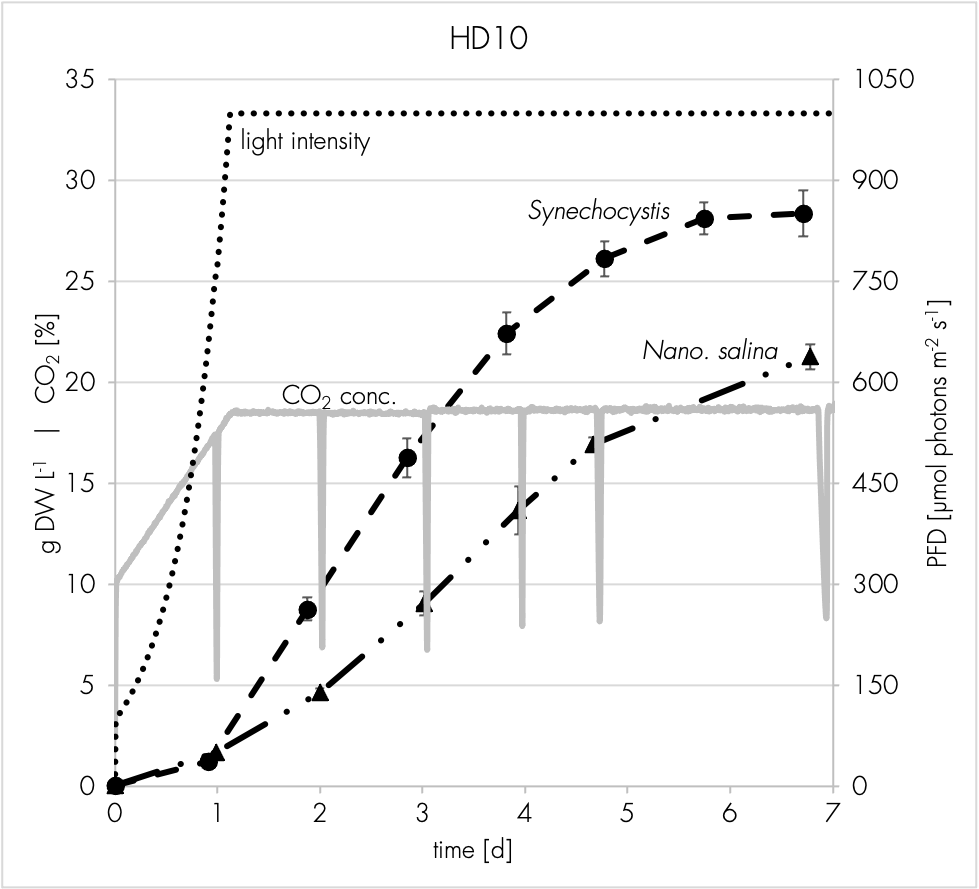

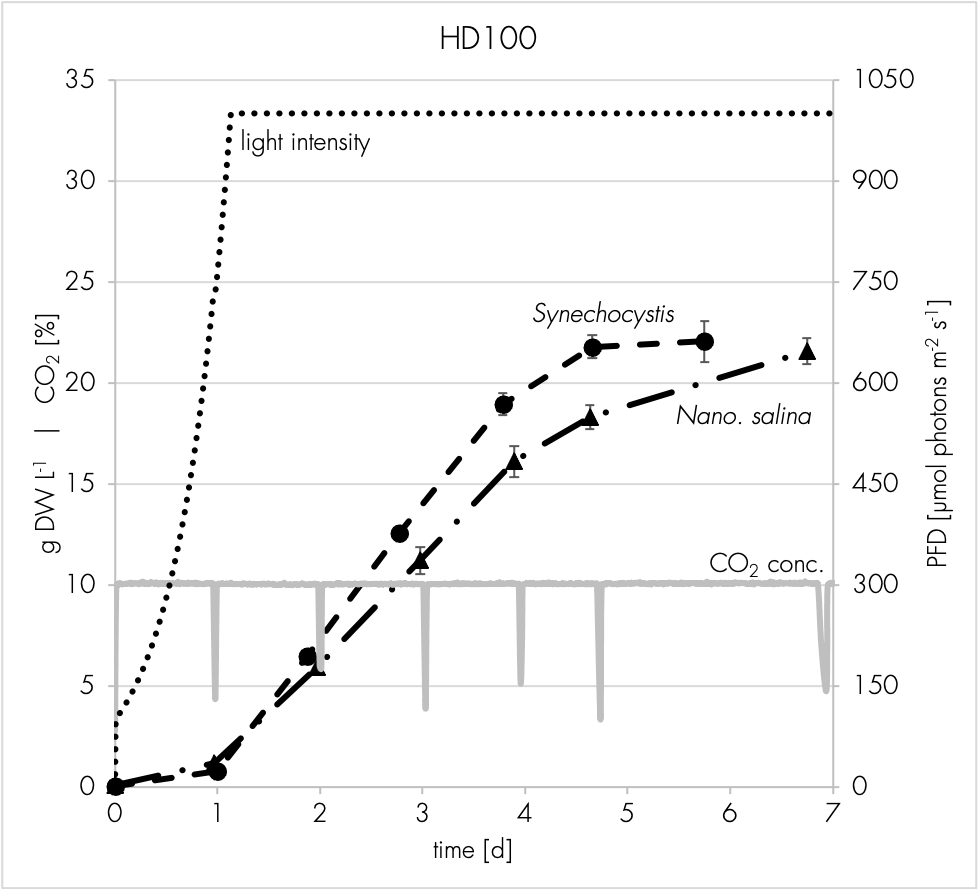

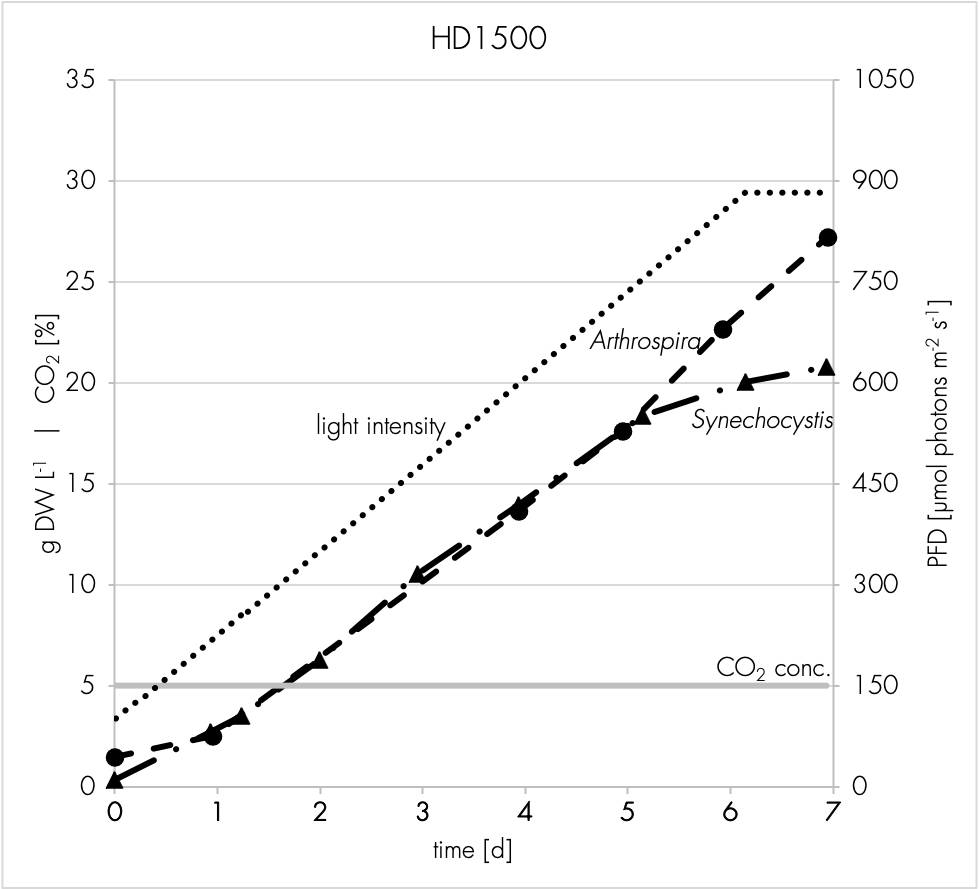

biomass concentration up to 30g dry weight per liter

productivity up to 10 g dry weight per liter & day

no carbon limitation, no oxygen stress, no water vapor loss

high quantum yield at PFD > 1000 µmol photons m⁻² s⁻¹

axenic cultivation in a closed system

screening systems with up to 45 replicates

For more information, see the techonology page

Cultivation Systems

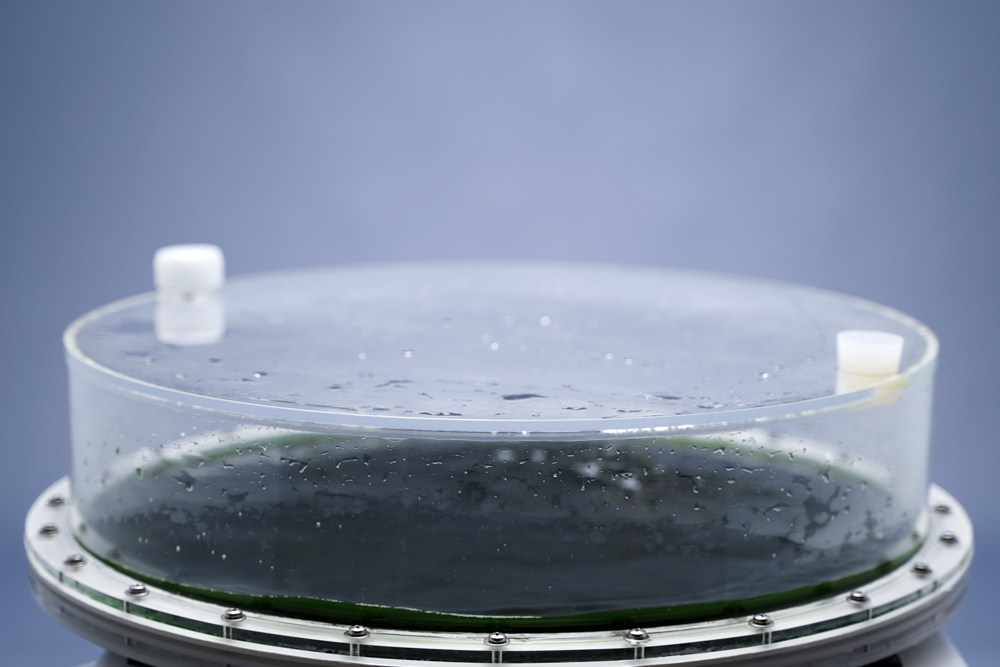

Uniform features of this reactor technology are turbulently moving cell suspensions with low layer thickness, a highly permeable basal membrane and closed (gas) compartments. We have realized laboratory-scale reactors (10, 100 and 1500 ml) as well as special reactors on demand. The cultivators are particularly suitable for parallelized cultivation of any research questions as well as preparative approaches for the production of high-density biomass.

For more information, please visit the product page

Testimonials

Parallelizable, Replicable, Transferable, Scalable

A number of studies have shown that the parallelized HDC cultivation systems reproducibly deliver results that exceed those of classical approaches in a multiple manner. It has also already been demonstrated that this significant increase in productivity is transferable for a wide range of species and can be achieved in different volumes.

Control technology and sensors

In addition to the cultivation platforms, we offer the corresponding control and regulation technology, sensors for cell density measurement (online or non-invasive samples) as well as appropriate devices for temperature control and illumination. For more information, please visit the product page.

CellDEG GmbH

Prinzenallee 78-79

D-13357 Berlin

GERMANY

Tel.: +49 30 2433 1959

Fax: +49 30 2433 1961

email: mail@celldeg.com

web: www.celldeg.com